Cigar Factory Tour in Honduras – CLE, Eiroa, OSOK, and Asylum

By By Anthony's CIgars on Feb 28, 2015 in News

It’s every Cigar Aficionado’s dream…

… Traveling internationally, smoking cigars and living it up with other cigar enthusiasts across the globe. It’s a dream that few people get a chance to experience – partially due to a lack of publicly accessible tours, and partially due to expense. So you can imagine my cloud nine like demeanor when Matt Bitter, our representative for Asylum, OSOK, CLE and Eiroa wrote me to ask if I would be up for a Cigar Factory Tour in Honduras to visit the factories and learn about their cigar lines.

- The Deep Fried Mac, Cheese, and Bacon bites were good though. Image © Anthony’s Cigar Emporium

Courtesy of Mike Teufel (the owner of Anthony’s Cigar Emporium), and the wonderful folks who work with Christian Eiroa (CLE, Eiroa), Edgar Hoill (EH, OSOK), Tom Lazuka (Asylum), my coworker Alex Jarkowski and I excitedly, (er… humbly) accepted the offer.

Flying from Tucson to Dallas, a 3 hour layover in Dallas, and then from Dallas to Miami, Alex and I were a bit… eh… underwhelmed at first. This being our first international flight, we were kind of hoping for excitement the whole way through – customs and paperwork and constantly whipping out our passports and boarding tickets. But really, it was a whole lot of waiting.

… Until we got to Miami, anyways. Then, oh then, the party started. As soon as we stepped out of the plane and into our $40, 10 minute cab ride from the airport to the hotel, we immediately met up with the guys who would be joining us on the trip, and lit up our first cigars of the 5 day journey.

- From left to right, Kole of Cigar King, Paul of Big Sticks Fine Cigars, Freddy of Jerry’s Cigars, Lenny of Owl Ear Cigars, Brad of Fumar Cigars, and not pictured, Mike Leese, Matt Bitter, the rep for Eiroa / CLE / Asylum, and Alex Jarkowski of Anthony’s Cigar Emporium. Image © Anthony’s Cigar Emporium

Full of Fried Pickles and other pub fare, we wandered back to our respective hotel rooms and hung out for a bit. Smoking a few additional cigars, and talking about the journey ahead, we stayed up until we were too excited and tired to continue.

Little rest was had, however, before the final leg of the journey into Honduras.

Day 2

And quite the leg it was. Mike and I were the only souls who decided that a checked bag was a good idea (which paid off later, but really, when you’re waiting 1hr 45 minutes to check in your bag at 8am, our situation looked grim. Travel Tip: I’d advise you take two carry ons and if you want to load one up and check it in later, you’ll save yourself a headache.)

But, 6 hours later, and landing safely in Honduras, spirits were high once more.

- Obligatory Selfie. After 6 hours + in an airport, the first thing I needed was a cigar. Luckily, we were greeted at our 11 seater van with a box full of Eiroa Capa Banda Tripa Maduros. Image © Anthony’s Cigar Emporium

The 11 of us got picked up by none other than Tom Lazuka of Asylum Cigars, and Edgar Hoill of OSOK, for a 3 hour adventure van ride to Christian Eiroa’s house, in Danli. Christian, unfortunately, couldn’t be with us as he was celebrating his daughters commencement.

- Cute, fully furnished, and comfortable rooms. Sudden relaxation set in immediately. Image © Anthony’s Cigar Emporium

After the drive (during which, when a “baño” was requested, we pulled over and utilized the local vegetation), we were shown to our own rooms, complete with rocking chair, two beds, fully functioning bathroom, shower, and beds more comfortable than even our Donald Trump “Luxurious” hotel in Miami.

From there, we took in the view – the wonderful Jamastran Valley, the house where we ate most of our meals, and spent most of our nights (kind of headquarters, really), and the cute little yappy guard dogs.

Breathtaking view of Jamastran Valley from Christian Eiroa’s Patio. Needless to say, pictures will never do the view true justice.

Image © Anthony’s Cigar Emporium

Day 3

After incredible food, and getting a good night’s rest, we set off bright and early to visit the Farms, where we got to see the progression of the tobacco plant itself, from seedling to harvest!

These Criollo Tobacco Seedlings were grown specifically for us, as they harvest season was just about over. Image © Anthony’s Cigar Emporium |

If I recall, these seedlings are 14 days old, and freshly planted in the field. Again, just for us, these little plants were already lush and beautiful. Our guide, Sandra, was awesome, and took her time explaining things for those of us who’s bilingual skill leaves something to be desired. Image © Anthony’s Cigar Emporium |

The final priming from the plants, we got to watch the Criollo Ligero be picked, and we wander around in the field for a bit. Image © Anthony’s Cigar Emporium |

From there, we went on to the Fermentation Barns, where they string up the leaves to oxidize, and age.

Men and Women alike strung up the leaves on long poles, 100 leaves per pole, where they were left to ferment for various time periods, depending upon the leaf being aged. Image © Anthony’s Cigar Emporium |

Barn full of fresh Tobacco leaves. The smell was wonderful – when someone says a cigar smells of “Barnyard”, this is the smell I will remember. Image © Anthony’s Cigar Emporium |

Tobacco Leaves after aging and fermenting. They had a unique, soft, silk feel in the hand, at this stage. Side Note – to make a Claro or Candela, you flash-age the leaf at a high temperature for 48 hours. It bakes the chlorophyll, not giving it the chance to brown. Image © Anthony’s Cigar Emporium |

It. Was. Incredible. There were something like 26 of these barns full of tobacco, in various stages of aging. We skipped around from barn to barn, seeing the various stages, and getting to touch the leaves throughout. From the rough, toothy early stage, to a soft, silky stage at the end, it was incredible to see how much time and care was put into each leaf that goes into a smoke.

From the barns, the leaves get bundled up, and put in to big bundles called Pilons, or large piles, where they are covered and left to “cook”. Basically, during the aging process, the leaves give off heat and humidity, which must be closely regulated. Different leaves like to “cook” at different temperatures – some as high as 120 degrees Fahrenheit. If it gets too high, or too low, the bundle must be torn down and rebuilt. This process goes on from 1 to 9 years, at the Eiroa factory – so when you smoke a cigar that’s been aging for 18 years, a significant portion of it’s life has been spent in this bundle-form, aging for the right temperature, taste, and burn consistency.

The smell was relatively sweet at this point – not a lot of earth or leather, as I would have expected. Image © Anthony’s Cigar Emporium |

Lenny here is re-humidifying a bundle of aged Criollo tobacco; separating the leaves so they have enough room to breathe. Image © Anthony’s Cigar Emporium |

A Pelon of Criollo leaf, being built. Putting the leaves together, and then covering them to “cook”, age and ferment. Image © Anthony’s Cigar Emporium |

After looking at a bunch of the weird, self-invented tech used to rehumidify the leaves (from large rooms with AC, to relatively hot rooms where it was definitely evident that the bundles were giving off significant amounts of heat), we moved on to a room where the leaves are sorted and de-veined by hand. Wrapper, Binder, Filler all get decided here, and once everything is sorted, the bundles are once again rebuilt, this time with flattened leaves of all one type.

These leaves have already been sorted and de-veined; they’re all Criollo, wrapper, binder and filler. Image © Anthony’s Cigar Emporium |

Once sorted, the leaves get piled into neat piles that then go back on to a pallet. Image © Anthony’s Cigar Emporium |

A Pallet of Criollo Wrapper leaves, which is then shipped off to the rollers. Image © Anthony’s Cigar Emporium |

One of the essential steps between here and final product is “Tasting the fire”; a process in which you take a random leaf from a pallet and light it on fire to see how it burns. If the Ash turns white, and it burns well, you’ve got a quality wrapper. If the ash is black, or the leaf has trouble burning, then essentially your whole batch is shot.

Tasting the Fire – letting the leaf burn to check for Ash quality, and leaf burn speed / quality. Image © Anthony’s Cigar Emporium

I was in awe. I love cigars. I’ve been smoking them since I legally could (18 in Arizona), and I’d tried just about everything in the Humidor. But it’s one thing to hear a cigar had been aged for “18 years”, and it’s another thing to see just how much love and work and care and caution had been put in to every stage of the process – from field to flash freezing and rolling. It was apparent to me at this point, too, that this “Cigar Factory Tour in Honduras” was much more than just a factory tour. It brought my appreciation for the craft to a whole new level – so much so that I asked Tom if tours like this were available to the public.

“There are no other tours like this.” said Tom Lazuka, of Asylum. NONE. Not only are tours like this roped off to vendors and people in the industry specifically, Tom explained, BUT Nobody else does everything in house.

I was stunned.

It’s impossible to appreciate just how much work goes in to the cigar you pick up at your local shop for $8 without seeing the entire process through, from start to finish. Impossible to even imagine – believe me. I knew everything about the whole process, and even then, I could not understand it until I’d seen it for myself.

Fortunately, Tom said, they’re looking into opening up tours to the public, once production ramps up and they figure out their new factory situation. The idea would be that if you can pay for the airfaire, they’ll cover the rest, and you would get to see exactly what I saw. It’s a long timeline – something like 2 years or more, before the thought will start getting turned into a reality.

But if you ever have the inkling – even the whisper of “I’d like to see that.” Go. Just go. Your smoking experience will be elevated beyond your wildest dreams; You will learn more and appreciate your cigars in a manner reserved for Fancy Dinners and Christmas Day Church Services.

Day 4

After another wonderful meal, and our trip already feeling like it was ending too soon, we got to spend our last day at the on-location Box Factory, the Rolling Factory, and then on to none other than a Coffee Plantation tour.

Christian Eiroa’s business is one of few that actually make their own boxes on location. Joined this time by Edgar Hoill (OSOK), we continued to have our minds blown as we watched the entire process from raw wood to lacquered box.

This group of guys planed the Cedar that would become the various boxes in which cigars are placed and transported. Image © Anthony’s Cigar Emporium |

This young gentleman worked the printing press, placing ink on the plates, and quickly inserted wood panels as the press opened and closed. Image © Anthony’s Cigar Emporium |

One of Edgar’s designs, the Jaguar King seen on his OSOK Boxes, this plate gets put through the printing press on the wood plate that will become the top of the box. Image © Anthony’s Cigar Emporium |

Asylum, Eiroa, CLE, and OSOK are moving towards all-cedar boxes that can also be used as temporary humidors. Emphasis on temporary – you should always make sure that your humidor seals tightly to preserve the humidity. But for those who may not smoke enough to justify a humidor (yet), an all cedar box is an awesome way to store your sticks, long(er) term, as along as you keep an eye on the RH.

In order to train new cigar Rollers, Christian’s father, Julio Eiroa, established a rolling school, where one studies to be a full fledged Torcedor. Image © Anthony’s Cigar Emporium |

How’s that for homework? This cigar was a new special blend by Julio Eiroa – formally, a Don Julio, I think. They let us smoke one, and man, keep your eyes open, cause when this hits the shelves, it’s gonna be big. Image © Anthony’s Cigar Emporium |

At the Cigar Rolling Factory – Tom, Matt, and Alex discuss the 8×80, Asylum’s newest offering. Image © Anthony’s Cigar Emporium |

From here, we got to roll our own cigars (or… re-wrap existing ones, rather), stopped for lunch, which was delicious, and then we moved on to the Coffee Plantation.

The cuisine was exquisite; These are called Pupusas – essentially two maize patties with cheese in between, covered in pickled veggies. Image © Anthony’s Cigar Emporium

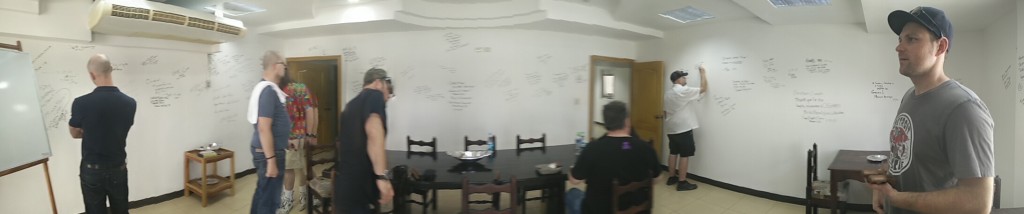

We all got to sign the conference room walls! Felt good to leave a mark. Image © Anthony’s Cigar Emporium

When we left, we were given the option of taking the Van we were all accustomed to… or riding in the back of the truck we’d be taking up the mountain into the Coffee Plantation.

A couple of us opted to ride in the back of the truck on the coffee plantation tour. Totally worth it. Image © Anthony’s Cigar Emporium |

A coffee plant with maturing beans; Once the beans are this bright red colour, they’re ready to be picked. By hand. Image © Anthony’s Cigar Emporium |

To call Honduras beautiful would be an unfair romanticization. It’s much more like a sea of activity, a little sketchy, and not somewhere you want to go without a guide, but as soon as you’re inside an establishment, it’s like each house is it’s own little oasis.

Post Coffee Plantation Tour – a little boutique hotel where we tasted the coffee we just saw growing. Image © Anthony’s Cigar Emporium

Sit down, relax, have a Cerveza, and smoke a cigar. Our life for 3 days in a row.

With the trip coming to a close, and all of us pretty tuckered out, we wandered on back to the house, for a final night of hanging out and enjoying eachother’s company.

Day 5 was entirely travel. We spent some time in the Duty-Free shops (which were not impressive – if you’re going to buy stuff, buy outside of the airport), but mostly, it was a quiet, solemn day, bidding farewell to the country and people who brought us such joy.

Sorry, comments for this entry are closed at this time.